Tuesday September 23, 2003

Tire and Wheel Tuning

When it comes to performance for

these little machines we love to race, round and true tires and wheels are the

foundation of it. Regardless if the rest of your model is blue-print perfect,

out of round tires or wheels will make your model suffer in performance. There

have been many ways discussed in the past on how to correct these problems, but

I have found a way that I feel is much simpler so I thought I would pass in

along to you.

When it comes to performance for

these little machines we love to race, round and true tires and wheels are the

foundation of it. Regardless if the rest of your model is blue-print perfect,

out of round tires or wheels will make your model suffer in performance. There

have been many ways discussed in the past on how to correct these problems, but

I have found a way that I feel is much simpler so I thought I would pass in

along to you.

It used to be that I would take my models and place them on the track with some sandpaper or Emory cloth under the rear wheels and apply some power. This method does still work and many of you use it today. However I have found that some tires need more work on them than others to get them where I like them, and holding the car over the sandpaper can get tedious during these times. I also have found that there are a few things you can do first before you begin sanding your tires that will help you get the results you want.

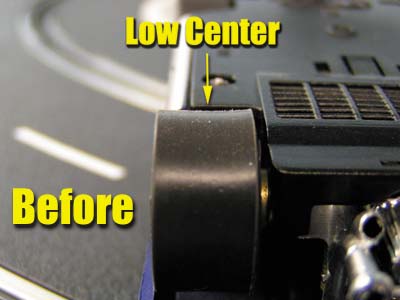

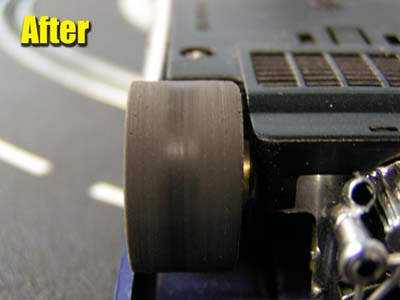

The first thing I do now before sanding is to remove the tire from the wheel and check to see if there is any excess mold flashing on the wheel that would cause high or low spots on the edges or center of the tire. If there are areas such as this, you can trim it away using an Exacto knife, or you can leave the tires off and sand the wheels themselves to make sure they are clean and true. For a fast clean-up of the wheel, I use some very fine grit sandpaper such as Testors brand finishing paper. Again it only takes just a few seconds to clean up the centers or edges of your wheels to have an even better fit of the tires. You can also use this method to "turn down" the center of a wheel to allow different sizes of tires to fit evenly across the wheel.

I also check the wheel to make sure it isn't cracked at the hub or that the wheel is mounted crooked on the axle. If it looks to be mounted badly, I have found that most times just removing it and replacing it yourself will cure the problem. Sometimes these wheels just need to be fully seated all the way to get them as true to the axle as possible.

After this I inspect the tire itself for mold flashing on the inside and outsides, and to see if the tire has any significant molding flaws in it that are too much to sand away. If the tires are this bad, I can only suggest getting a replacement or switching to silicone or PPR Supertires. Once this is completed, re-attach the tire to the wheel and make sure it is a snug, even fit. Sometimes your tires might need a little work by hand to get them fully seated on the wheel, so it pays to take a little more time in this department before you attempt to true them.

Once this is completed and I have the tire fully seated on the wheel, its time to get busy. All you need is a common 9 volt battery and a #408 or similar Sanding Band from Dremel. You can use other levels of grit but this is the one I prefer. Just take the car and hold it with your left hand as show with the battery in your fingers. Then have your sanding band ready on the tire where you want to start with and touch the battery to the pick-up braid.

Now just take the sanding band and hold it against the tire evenly while the wheels are spinning. You will quickly see the tire begin to true itself. This works great on rubber tires that really need a great deal of work with them, and the process is completed much quicker and with less stress on the motor as well.

This also works wonders on silicone tires as well. I recently tuned my Ninco Speedster with some help from Dave Dobner and Rich McMahon on their last visit, and they happened to have some Indy Grips on hand. After mounting them on the wheels they showed me how nicely this method works in truing up these tires and even adding a little sidewall rounding.

Now some of you might be concerned about getting these tires and wheels sanded evenly, making sure one side isn't bigger than the other. This concern is also present using the more traditional method of placing sandpaper on the track and holding the car over the paper as sometimes you get uneven pressure on the tires. There are 2 ways that I use to accomplish this, one is rather precise while the other is the faster, easier route.

Most times when I perform this maintenance only the tires need a quick scrubbing to get things right. In these cases I just sand each side and let the rubber meet the road. The diameter difference of the tires is usually so slight that I don't bother to measure them, and performance is still vastly improved. Is this precise? No...but it works...and for some of you out there this is all you will need to do to improve matters on your home track.

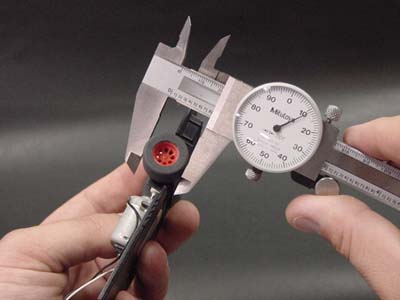

If your looking to get things as even and precise as possible you will have to measure your tires. Using set of calipers such as the ones shown, you can get your tires and wheels as close to a perfect match as you could ask for. Now I realize that not all of you have a set of these calipers on hand, but if you are the type that want precision, I highly suggest you make the small investment now. There are other ways to measure these diameters, but in my opinion using calipers are just the easiest route.

As with most technical information found today, no certain way is "the" best way for everyone, but I find this method extremely easy. Performing preventive maintenance like this really helps you appreciate and enjoy your models just that much more and I encourage all of you to give it a try and let us know your thoughts.

- Harry

If you have tuning methods you feel could help other enthusiasts, please contact me and I will do my best to get it published.