Saturday August 12, 2006

NINCO Classic Porsche 356

Some series of cars seem to find an immediate following in our hobby and the

Classic line by NINCO is no exception. Since the first releases of these cars

around 10 years ago, many enthusiasts have been enjoying a unique style of

racing that only these cars can deliver. Although they are a very different

style of model, this latest release has more to offer in the fun category than

you might think.

Some series of cars seem to find an immediate following in our hobby and the

Classic line by NINCO is no exception. Since the first releases of these cars

around 10 years ago, many enthusiasts have been enjoying a unique style of

racing that only these cars can deliver. Although they are a very different

style of model, this latest release has more to offer in the fun category than

you might think.

If you are new to the hobby, the past 10 years has produced a literal explosion in 1/32nd scale home racing. Thanks largely to the Internet, our hobby began to find its way into more and more homes across the country and the popularity of it expanded dramatically. When NINCO first arrived on the scene, some racers were more concerned about how many magnets they could fit inside a car and what silicone tires they needed for maximum speed. Some enthusiasts just did not care for these classic cars and soon NINCO seemed to shy away from producing them.

Over the years however, these Classics soon became models many racers desired. Outfitted with the mild, yet reliable NC-1 motor and no magnet, these cars were easily tuned for both plastic and wood track applications. This Porsche represents what I feel is the true spirit of the Classic line. Although NINCO lists other models such as the Austin Healey, Chevy Corvette, and Porsche 911 in this series, they have the larger motors and magnets in them which to me just doesn't put them in the same category.

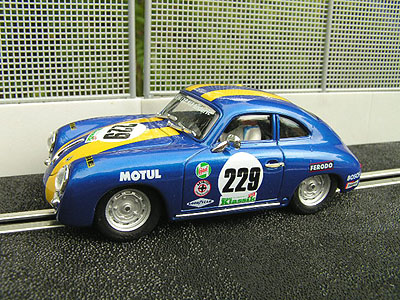

Our model arrived safe and sound from MRC and I was immediately impressed. The paint and Tampo stamped applications are simply outstanding throughout the model. I noticed no runs or fades is either of these areas and everything is sealed with a very clean clear coat. The deep blue paint is very attractive by itself but the added contrasting yellow stripes just make things even better for me.

The interior is the half-try type design and works perfectly for this model. Our driver figure is nicely detailed and the visible roll bars give it added scale appeal. Although some prefer a model that has extra fine details inside, I still prefer this level. It is more than enough for most scale enthusiasts and still allows room inside for tuning, which with these models is exactly what many want.

Wheels and tires are all standard NINCO and were fairly round and true. After trying different types of tires over the years, I have simply went back to the stock NINCO rubber and that is where I will stay for my plastic home track. Some different track surfaces might cause you to change to a high grade silicone or other after-market tire for best results. The only tire for this car I have tried is IndyGrips #2002 and it worked very well on several different routed wood tracks as well as decent performance on my older Carrera layout.

Out Of The Box Testing

My initial test runs out of the box found a functional model, but it was clear that a few modifications would be needed to suit my tastes. Still, the model ran as expected out of the box with nothing more than a braid adjustment so NINCO achieves the OOB (Out Of Box) Award easily. I tested on my Artin road course with my aftermarket power set at 12 volts and used PARMA 35 OHM controllers. After 25 laps in each lane my lap time averages were in the 6.7 second mark. Not a lightning bolt by any means, but still a fun model to pilot. On my NINCO test layout the car ran well using the standard power pack and the set 55ohm Plus controllers. It had just a slight more punch to it due to the voltage supplied and with the track being more abrasive, the sliding was a little more difficult to control but it was still fun to dice through the tight corners I had used.

On The Inside

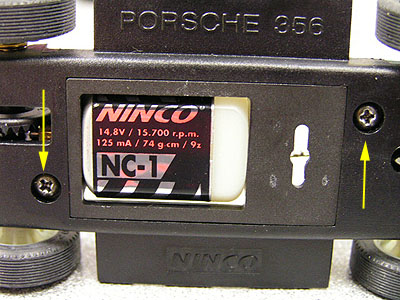

Turning the model over we see the NC-1 15,700 RPM Motor (Rated at 14.8 Volts) in the inline position. The body is mounted to the chassis with 2 screws that are easily removed.

You also see 2 additional screws front and aft of the motor. This is the motor mount bracket and it can be changed to accommodate motors such as the NC-2, NC-5, and NC-6. The part number for the bracket if you want to change motors is 80607 and usually runs you about $3.00 to $4.00. Personally though, the NC-1 has long been a favorite motor of mine and is just about the perfect match for this little Classic.

Modifications

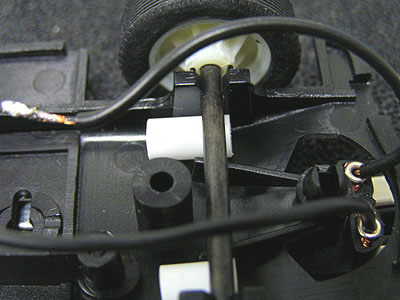

One of the first things I look for on these classics is front axle free-play, both vertical and horizontal. I was happy to find the axle had virtually no horizontal free-play which saves me from shimming or trimming the axle. However, the vertical free-play was excessive and it was time to perform a simple modification I learned years ago.

After removing the body, I placed the model on a spare piece of track I use as a set-up block. I then cut 2 small sections of styrene tubing (Evergreen Styrene #226 - 3/16" Tube) and placed them as shown in the photo. This reduces the free-play and decreased the amount of body roll to an acceptable level. On many models, excess body roll simply translates into a car that tips over too easily in the corners. Reducing this body roll helps transfer the force and power of the car to the rear wheels where it will tend to slide out instead of tipping. On this model, the tipping effect is increased due to the tall body style.

This single modification greatly improves the overall performance of this model and I can only suggest trying it yourself to feel the difference it can make. Don't feel you have to go out and purchase this tubing, as you can use virtually anything to finish this modification. I'll bet you have an old model kit laying around somewhere and you can use the old sprue from that in many cases.

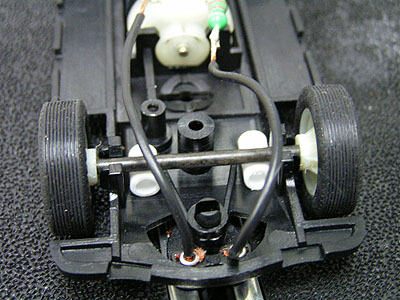

You can also benefit from checking the motor while applying power to see if it is rocking in the mount. If so, a small drop of hot glue on each side will resolve this issue. You also might want to add adhesive over the rear brushings to keep them securely mounted in the chassis and prevent them from spinning under load. My model had no signs of this happening, but as a preventive maintenance measure I added a small drop of hot glue over the tops of them.

Wheels & Tires

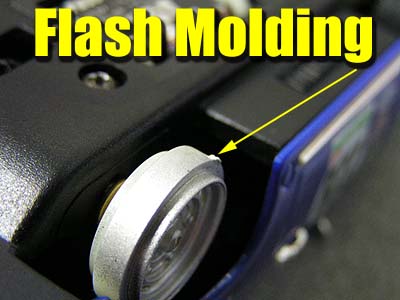

Next I look to the wheels and tires. Many NINCO and other brands of models can see a large improvement in smoothness of operation if you take the time to make sure the wheels (particularly the inner rib where the tire is seated) are clean of any excess flash molding and that this inner rib and also the outer edges are as true as possible.

Our model is a perfect example as the first rear tire I removed revealed this very problem. A noticeable piece of flash molding was right on the outside of the wheel and needed to be removed so that the tire would seat as cleanly and true as possible on the wheel. To clean these wheels I use the same method that I have used for years.

I use a very fine grit sandpaper and while the model is under power I lightly touch the sandpaper to the wheel until I can see and feel that all the excess flashing is removed.

This only takes a few seconds and then you are ready to re-install the tires and begin your first sanding session. For the front wheels I just use a small Exacto knife and trim this excess away, then lightly go over it with the same fine grit sandpaper.

Sanding your tires is accomplished many different ways and the type of tire and car can dictate what is the best method. A dedicated sanding station is the answer for me in cases such as our little Porsche here.

Placing the model on the sanding station as shown, I sanded the tires for about 30 seconds and then cleaned them by running them over masking tape. Some heavier tape can leave too much residue on your tires so I prefer to use plain old masking tape that is found everywhere. Once this was accomplished it was back to the track to see if I have improved the handling.

Extended Testing

The first few laps told me that the small amount of work I have accomplished really improved the model. Now, instead of a car that wanted to roll over every time I applied too much throttle now would swing out more than half the time. This gave me a easier handling model in the tighter corners and allowed me to simply negotiate them faster. Lap time averages were now easily in the 6.0 second range which is a vast improvement.

Many enthusiasts will want to add lead to this model to increase performance even more. However, the desired weight and placement of it will vary dramatically as each track is different. Some race on wood, others might have small twisty designs, while yet others have very large layouts with broad, sweeping corners. I can only advise you to just experiment with your current layout and find the right answer for you.

Final Thoughts

The NINCO Classics have long been a favorite series for me and I couldn't be happier with this release. Having NINCO return a series of models such as this proves to me that they do listen to enthusiasts and try to deliver products that we ask for. We do not always get them of course, but the announcement of this model caught me by surprise. The many enthusiasts who truly appreciate the mild NC-1 motor should not have to worry about it going away anytime soon. I hope to see more models in this series in the future and perhaps bring back the other very popular cars as well.

If you enjoy a challenge in your driving, this car just might be for you. Having lightning fast heavy magnet cars is fun, but sometimes a model like this is equally as fun if you allow it to be. Having 4 of these cars slicing and dicing through the corners is just as satisfying as any other series of models in my opinion. If you are looking for something different in our hobby, I highly suggest giving this Classic a closer look.

- Harry

As always feel free to contact me about this article or just the hobby in general at harry@homeracingworld.com, or better yet drop into our Message Forum and share your thoughts with other enthusiasts!

Thanks Go To MRC For Providing Us With This Sample!