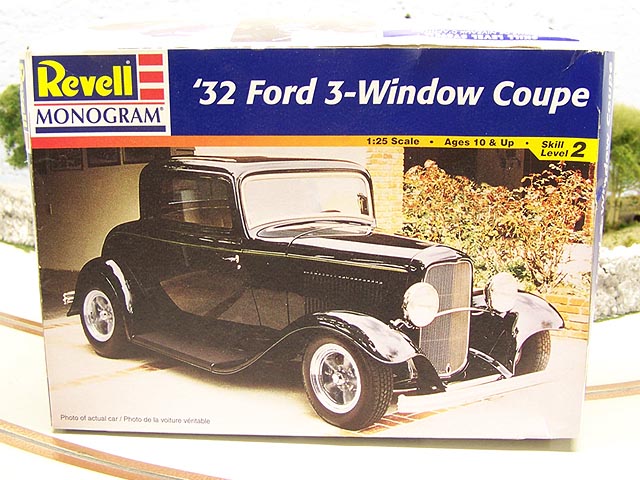

"The Deuce"

What we like about 1/25th - 1/24th scale is how much you can do with it.

With the wide range of models available, you can build almost anything you can imagine.

Here we are taking another innocent street rod and making a Saturday Night Modified out of it.

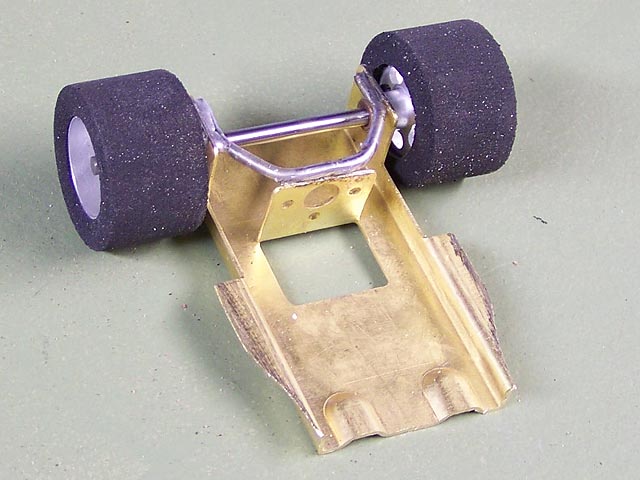

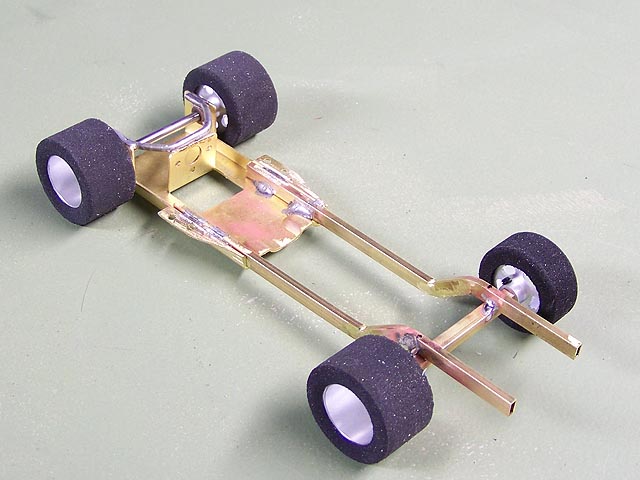

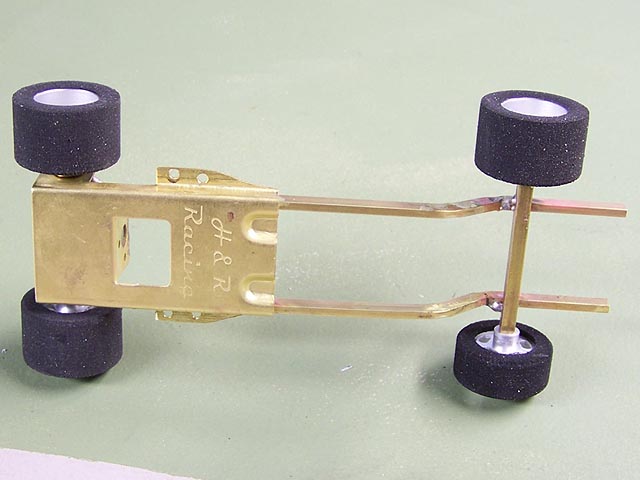

Our first step is to start on the chassis. This is the H&R chassis that has been heavily chopped.

For the modifieds, I end up just using the rear bulkhead. As you can see above, it then gets cut and trimmed leaving only 2 small edges where we drill holes to allow the body mount screws.

NOTE: I have heard some enthusiasts say that it seems a waste to purchase a full chassis when I am going to scrap half of it.

The truth is I do not "scrap half". The only item not used is the front bulkhead. The rest of the chassis and components are used.

Wheels, axles, gears, motor, wire, guide, and axle bushings all are utilized.

I do not carry a surplus of 1/24th scale commercial parts. Buying it by the part would much more expensive than a complete chassis.

I buy all my chassis from www.slotcarplace.com part# HRCH01 for $39.50

If you do have a surplus of parts you can just order the bare chassis part# HRCH02 for $22.50

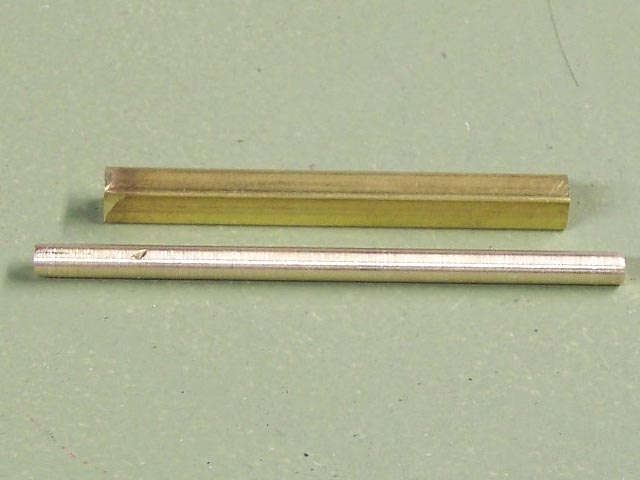

Time to make the front axle and housing.

Here is how I set the width. I just match the front with the rears. Then measure the inside to get the length for the axle housing.

NOTE: You may notice I am using 1/8 brass rod for our front axle. We get this brass rod at Lowe's or any other home center.

We do this as this is all it really needs up front and we save the good steel axle for use in the rear of other models.

The next step is to make the front axle housing.

I like using square tubing to hold the axle. Why? Because it is just easier to adjust and set on the frame rails for soldering.

K&S 5/32nd Square Tubing Stock# 152

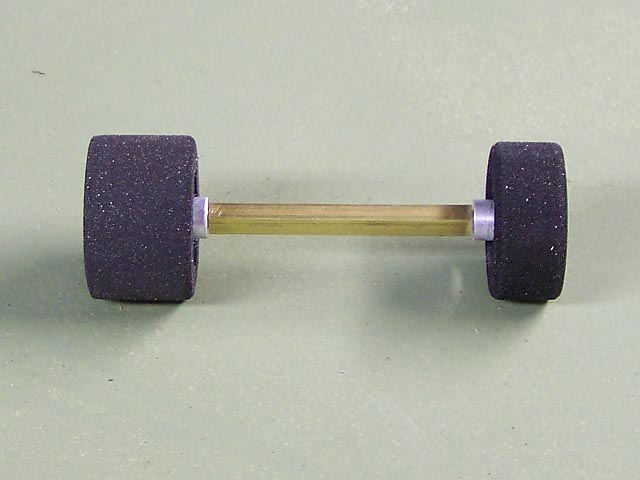

NOTE: You notice the brass front axle has been sanded. You can chuck it up in a ordinary drill and apply some fine grit sandpaper to it.

This really cleans and polished the brass quite well.

The front axle is completed.

Here you see why I like the square tubing so much.

We place the axle housing where we want it and hold it in place with alligator clips then solder.

I like using this "frame rail" brass stock from K&S Engineering.

I measure then bend the stock in a vise.

K&S 3/32 x 3/16 Rectangle Brass - Stock# 262

We make our guide tongue out of scrap brass sheet.

Next we mount all the bars. Get creative here. None of our models ever come out the same.

I clean and sand the brass, them primer and paint.

Test fitting the body.

Completed.